- Carbon steel Pipes Manufacturers & Suppliers - Seamless/Welded Pipe in India!

- Call us on

- +91-9930386661

- Send your mail at

- sales@steelpipings.com

- Working Hours

- Mon-Sat:9.30am to 7.00pm

Quality

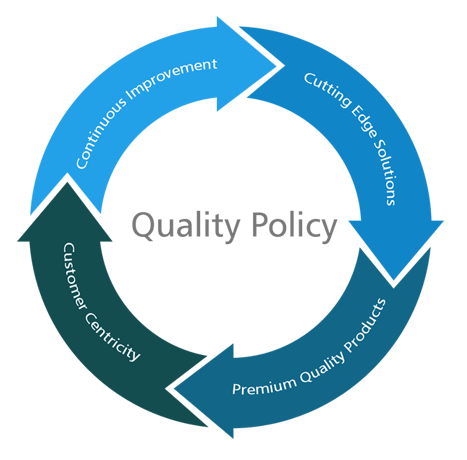

Quality Policy

Being a quality conscious and reputed name of this domain, we believe in establishing and maintaining a long-term relationship with our customers by providing them an unmatched quality. In order to maintain our reputation in various industries we are committed to furnish superior quality products at economical price with schedule consistency. It is our endeavor to follow the principles of total quality management. For our pursuance of Total Quality Management system, we have received ISO 9001 : 2008 certification.The company has developed quality objectives and work plans for quality management. We follow stringent quality control norms by reviewing and monitoring each production processes. These allow us to upgrade our quality processes to superior levels.

We strive to achieve the goals through process control, adherence to Quality System, Continuous Improvement and Total Employee Involvement.

Quality Control

The company adheres to stringent quality norms for all the processes. The materials are of very high quality and compatible to the latest machinery and production process. The company's technical and commercial quality guidelines are set to high standards. A team supervises the quality assurance and control aspects along with the entire process system by identifying and associating with the quality circle. Quality Control tests are conducted regularly to maintain a uniform product quality.

Material Control System

The incoming material specifications are co-related with Raw Material test certificates of the material. The checks and test are documented. The material is given internal control No. and same is recorded for future reference.

Process Control System

Forging and interim heat treatment in the process control reduces the chances of introduction of variables in the process. Each lot of pipes and tubes as defined in ASTM specifications are subjected to heat treatment and testing. Testing is performed in accordance with specification requirements. Test data is evaluated by QA department and recorded in appropriate format, supplementary test like radiography, ultrasonic, corrosion testing etc. is done as per code guide lines.

International Quality Standards

Our Pipe and tubular products are manufactured in complete compliance with leading regulatory standards in the domestic and international segments such as the IS, ASTM/ANSI, ASME, BS, JIS and DIN standards. These certifications are reflection of our commitment of providing quality products to customers around the world.

Shiv Sadan 2nd Floor, 154-156,

3rd Kumbharwada Lane,

Mumbai – 4000 004 (India)